For the hundreds of millions of diabetes patients worldwide, the continuous, stable and precise management of insulin intake is essential. Although long-term insulin pumps have significantly improved patients' quality of life, they still face challenges such as high purchase costs, inconvenience, limited privacy and high maintenance costs. Additionally, the large and heavy drive structures, difficulties in integrated applications, and complex production of components continue to be key technical problems for industry R&D.

In recent years, disposable insulin patch pumps have gained attention as an innovative technology. With the advantages of single-use design and precise drug delivery, they have the potential to revolutionize the medical device market for diabetes management.

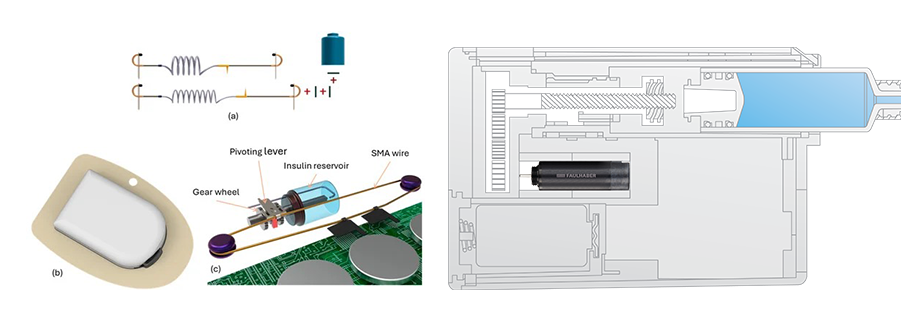

▲ Diagram of Various Drive Mechanisms

The driving force behind this technology lies in its drive mechanism. From motor drives and shape memory alloy drives to MEMS (Micro-Electro-Mechanical Systems) technology drives, these advanced drive mechanisms are evolving, driving the upgrade of disposable insulin pumps. What are the characteristics of these various mechanisms? How does one choose the appropriate drive mechanism? What requirements are there for insulin pump drives? This article will explore the current status and future trends of disposable insulin pump drive mechanisms.

Disposable Insulin Pumps: The Future Direction of Diabetes Management

Long-term insulin pumps, which use motor drive, have issues such as relatively high cost, large size, heavy weight and unable to adhesive use, requiring tubing for infusion. Patients using these insulin pumps often face risks such as poor privacy, tangled or blocked tubes, and bent soft needles.

Additionally, many studies on diabetes patients have shown that the convenience of insulin injection devices greatly affects medication adherence. In response to clinical feedback and ongoing R&D, a smaller, lighter adhesive insulin pump has emerged. Characterized by its adhesive, single-use design, it is often referred to as a disposable insulin patch pump. According to relevant clinical trial information released in 2024, this type of pump outperforms tubed pumps in blood glucose control.

The advent of disposable insulin pumps, with their more convenient self-administration experience, has significantly improved patients' quality of life, signaling the future development of diabetes management. For such innovative medical devices, the core component—the drive—must be designed to ensure precise drug delivery while emphasizing miniaturization and ease of use to meet modern lifestyle needs.

Shape Memory Alloy Drive: Pioneering Disposable Insulin Pumps

In 2005, the world's first disposable insulin pump was launched, with a compact and lightweight design concept that gained market recognition. This shape memory alloy drive device incorporates various precision components, such as a drive shaft, lead screw, spring, and cam, which require high-precision assembly and coordinated operation. It advances the reservoir piston and delivers insulin through the cannula, delivering 0.05 units of insulin per time.

This innovation disrupted the long-term insulin pump market, and due to exclusive patent restrictions, insulin pump manufacturers that previously relied on servo motor drives began actively exploring new drive solutions and the development of disposable insulin pumps.

Piezoelectric MEMS Micro Pump: A New Drive Technology for Disposable Insulin Pumps

As an intelligent control input device, insulin pumps must meet high-precision injection control requirements while offering the advantage of adhesive wear, to successfully mimic the body's physiological insulin secretion. Differing from shape memory alloy technology, the piezoelectric MEMS micro pump technology, developed by YW MEMS and launched globally in 2024, opens a new technological pathway for disposable insulin pumps.

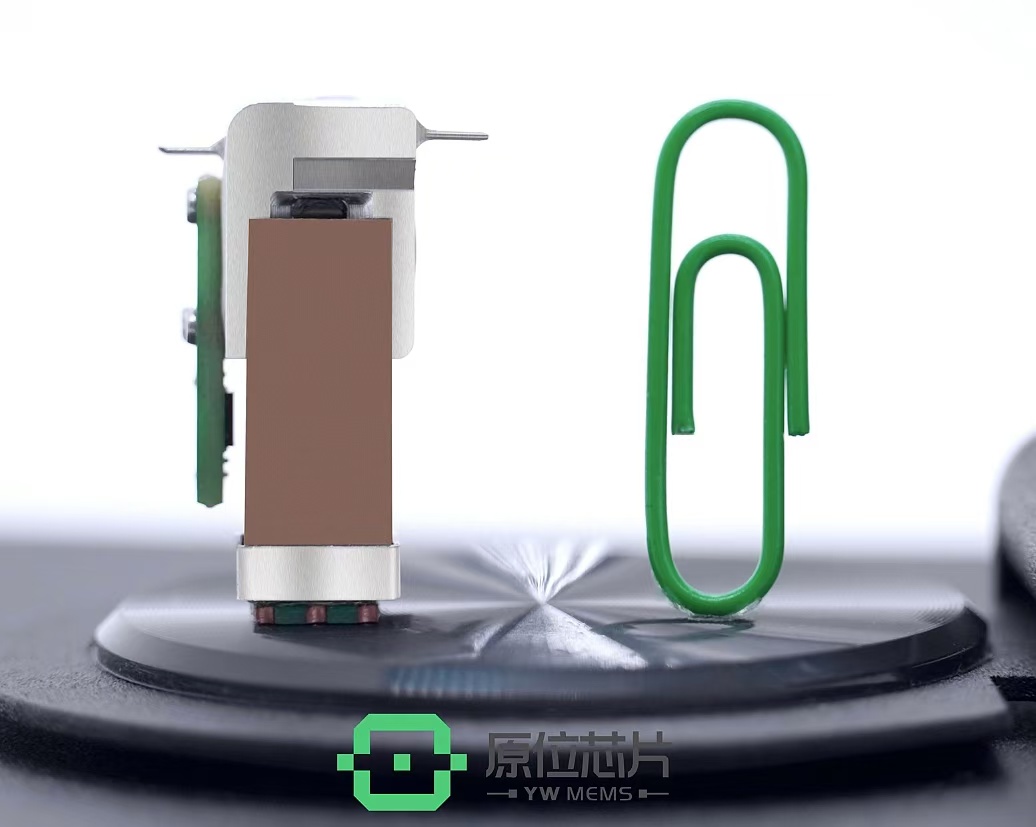

▲ Comparison of MEMS Micro Pump and Paper Clip in Size

The MEMS micro pump drive is a piezoelectric volumetric pump with core components that include an independently developed MEMS chip by YW MEMS company, piezoelectric ceramic, and electrical-fluid interface. The MEMS chip functions as the pump chamber, with a volume measured in nanoliters, and integrates unidirectional valves at both the inlet and outlet to ensure one-way fluid flow and excellent sealing, enabling outstanding pumping capacity under high pressure. The piezoelectric ceramic drive enables single, low-frequency, interfered pumping strokes control, achieving a precision of ±4.5% per pumping.

Additionally, MEMS technology has significant advantages in component integration. The number and complexity of parts affect the manufacturability, maintainability, and reliability of the insulin pump. Thus, the MEMS micro pump drive adopts an integrated modular design, reducing the number of parts and potential failure, aligning perfectly with the stringent requirements for drive systems in disposable insulin patch pumps.

▲ Photo of MEMS Micro Pump Displayed at CMEF Shenzhen Exhibition

Since the first insulin pump was launched in the 20th century—initially requiring a backpack-like device—research and innovation in insulin pumps have continued, shrinking the device to matchbox size and making it suitable for direct adhesive use by the 21st century.

As an innovative drive solution, MEMS micro pumps, with their high precision and modular design, demonstrate exceptional convenience and reliability. YW MEMS will continue to advance piezoelectric MEMS drive technology, accelerating the rollout of disposable insulin pumps driven by MEMS micro pump to fill the gap in the domestic market for disposable insulin pumps.

▲ Some images sourced from the internet