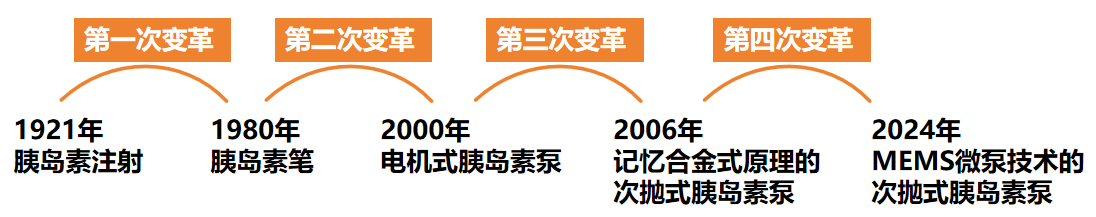

“MEMS micropumps are triggering the fourth revolution in insulin therapy.” Shuo Ma, founder of YW MEMS, shared.

Insulin was first discovered and used to treat type I diabetes in 1921. The treatment at that time was subcutaneous insulin injections.

In 1980, with the advancement of technology, insulin pens were developed based on traditional syringes, which are smaller in size and easier to use. However, patients still need multiple injections every day, and each injection leads to rapid fluctuations in insulin concentration, which cannot mimic the physiological delivery of insulin, resulting in less than 40% of patients' blood glucose compliance rate, and they are still at a high risk of diabetic complications.

In the late 1990s, motorized insulin pumps were introduced, which used a servomotor to drive a screw rod connected to the reservoir to infuse insulin subcutaneously, realizing continuous subcutaneous insulin injection at CSII combining basal rate and meal rate to reduce the glucose fluctuation caused by the dawn effect. However, servomotors are expensive and have a high initial cost, with patients requiring tens of thousands of dollars for a single purchase. In addition, patients need to have the skills and understanding of the device to reassemble the reservoir, battery and other components on a weekly basis on their own.

In 2006, Insulet launched a memory alloy type of disposable insulin pump, which utilizes the reciprocating deformation of the memory alloy under heat dissipation conditions to pull the gear set and screw movement, thus replacing expensive servo motors, and can provide a fixed rate of continuous fast-acting insulin within 72 hours.

Although Insulet designed the entire insulin pump to be miniaturized, patchable and disposable, the core drive module is not sold separately and is limited by the technical principles, resulting in limited upgrading space for dose and daily cost.

However, the medical device market is in dire need of disposable core drive solutions to support product development and innovation. So, can MEMS technology break this deadlock and provide the market with more innovative drive modules by launching a new generation of disposable insulin pump?

With such thinking, YW MEMS has been dedicated to research and development for many years, and successfully developed a MEMS-based insulin micropump module. The disposable insulin pump developed based on this module has the advantages of low initial investment cost, low average daily cost, low dose and high degree of modularity. The dose is as low as 0.01U, which will help the blank of the domestic disposable insulin pump market, enhance the cooperation between the upstream and downstream medical device companies in product development, and is expected to set off the fourth insulin therapy revolution.

insulin therapy changes

Tsinghua alumni join hands with CAS microelectronics experts to start their own business

YW MEMS was founded in 2015 by microelectronics professionals from Tsinghua University and Chinese Academy of Sciences. The company focuses on the R&D, production and sales of micro-pump infusion modules, medical liquid flow sensors and silicon nitride membrane chips, as well as providing MEMS process development and tape-out.

After 9 years of intensive cultivation, the company has mastered more than 60 leading MEMS technologies, full-stack R&D and production capacity and has received tens of millions of investment from Sequoia China Seed Fund, Unlimited Fund SEE Fund, Miracleplus and other top VC organizations in China.

Shuo Ma, the founder of YW MEMS, has a master's degree of Micro-Nano Electronics of Tsinghua University under the supervision of Prof. Tianling Ren. During his study, he focused on the research of microelectron mechanical system chip, which has a broad application prospect in consumer electronics, industry, automotive, medical and other fields. However, more than 90% of these key chips have been imported for a long time, especially in the medical field, the monopoly of MEMS chips is particularly serious.

Faced with such a huge challenge, Shuo Ma saw a rare opportunity and the responsibility and mission of microelectronics. After graduation, he resolutely founded YW MEMS, aiming to provide China's medical device industry with independent research and development of the “Chinese chip”.

Shuo Ma, YW MEMS founder

At present, YW MEMS focuses on the MEMS micropump and MEMS medical liquid flow sensing technology platform. Among them, the MEMS insulin micropump module, has attracted particular attention. It provides high-precision and low-cost solutions for downstream manufacturers, and is expected to help the breakthrough and popularization of domestic and foreign disposable insulin pumps.

Self-developed MEMS insulin micropump module, realizing 0.01U insulin supply with high precision

MEMS micropumps, or Micro Electromechanical Systems micro pumps, are small pumps manufactured using micromachining technology, capable of transporting and controlling fluids on a microscopic scale. It is characterized by small size, light weight, low power consumption, low cost and precise operation. It is suitable for a variety of application scenarios of precise drug delivery and microfluidic control.

The technical advantages of MEMS micropumps lie in their high precision and controllability, which enable fluid delivery at the nanometer scale, provide ultra-smooth and ultra-silent droplet delivery, and have the ability of fast response and precise control. In addition, MEMS micropumps can be integrated into complex systems, such as automated drug delivery devices and microfluidic experimental platforms, thereby improving overall system performance and efficiency.

YW MEMS has spent 5 years to develop and produce its own MEMS insulin micropump module for high-precision insulin injection through the combination of “silicon-based micropump chip and piezoelectric ceramic driver”.

medicinal micropump module

The core of the micropump module is mainly composed of two parts, the micropump chip and piezoelectric ceramics. After receiving the control signal, the piezoelectric ceramic undergoes reciprocal deformation based on the inverse piezoelectric effect and acts on the pump chamber of the micropump chip. A one-way valve and a variable-volume pump chamber are integrated within the micropump chip based on a semiconductor process. Driven by piezoelectric ceramics, the micropump chip draws in and outputs a fixed volume of liquid at a time.

This solution skillfully avoids the high cost and volume problems caused by the servo motor driver that requires complex components integrated into the micro-electromechanical chip, and also breaks through the limitations of the memory alloy driver in terms of accuracy, and has a fault detection and occlusion alarm function. Its pumping accuracy reaches ±5%, pumping the lowest dose up to 0.01 U. While significantly reducing the size of the pump body and lowering the manufacturing cost, it improves the high-precision drug delivery control, and the maximum output pressure reaches 16 Psi.

micropump module smaller than #5 and #7 batteries

In addition, YW MEMS has self-developed a special packaging process and applied for a number of patents. Moreover, the entire module is originated from the domestic supply chain, which can provide a stable and reliable supply for downstream manufacturers.

“Our MEMS insulin micropump module is safe, reliable and highly modularized. Downstream manufacturers get a module with high comprehensive performance, consisting of a micropump chip, pressure sensor chip, etc., which can realize both pumping and pressure detection. It not only helps downstream customers' products have a more concise and clear internal structure of the product, and it is easier to guarantee the reliability of medical products.” Shuo Ma added.

It is reported that YW MEMS insulin micropump module has been favored by many insulin manufacturers, and expect to replace the currently used motor, so as to launch low-cost, high-precision disposable patch insulin pumps, in order to satisfy the market's urgent demand for efficient, convenient, and cost-effective insulin therapy solutions.

In addition, the module can also be extended and applied to biomedical enterprises to launch single-used drug injection micro-pumps for animal drug experiments and sustained-release drugs. Realize precise injection supply of anesthetics, analgesics and other drugs.

Full-stack self-research and patent layout create a moat and have entered the commercialization stage

The application of disposable insulin pumps has been widely proven overseas. According toInsulet, by 2023, about 425,000 people around the world are using its Omnipod insulin pump system, with an annual revenue of 1.7 billion U.S. dollars. In the same year, the approval of domestic disposable insulin pumps is blank.

The core components are the key factors causing this gap. Shuo Ma further revealed the three major difficulties: first of all, the process design of the secondary insulin pump and the chip design of the patent barriers, which constitutes an important obstacle on the road of research and development; secondly, the know-how of the process is also a hurdle, the introduction of new devices requires new processes to match, including patent protection for packaging processes and support structures; Finally, the design and development of internal supporting modules should not be ignored, which involves circuit design and many other technical aspects. After years of hard work, YW MEMS has realized full-stack self-research from chip to module, and completed 27 patent authorizations.

At present, YW MEMS's self-developed MEMS medicinal micro-pump module and medical liquid flow sensor has reached a deep cooperation with a number of insulin pumps, clinical monitoring equipment and other types of medical equipment manufacturers, filling the gaps in the domestic market for related products. Next, the company will actively plan to build its own chip, packaging and testing production lines, in preparation for the subsequent production capacity.